Email: info@massfilling.com Tel: +86 133 5803 8863

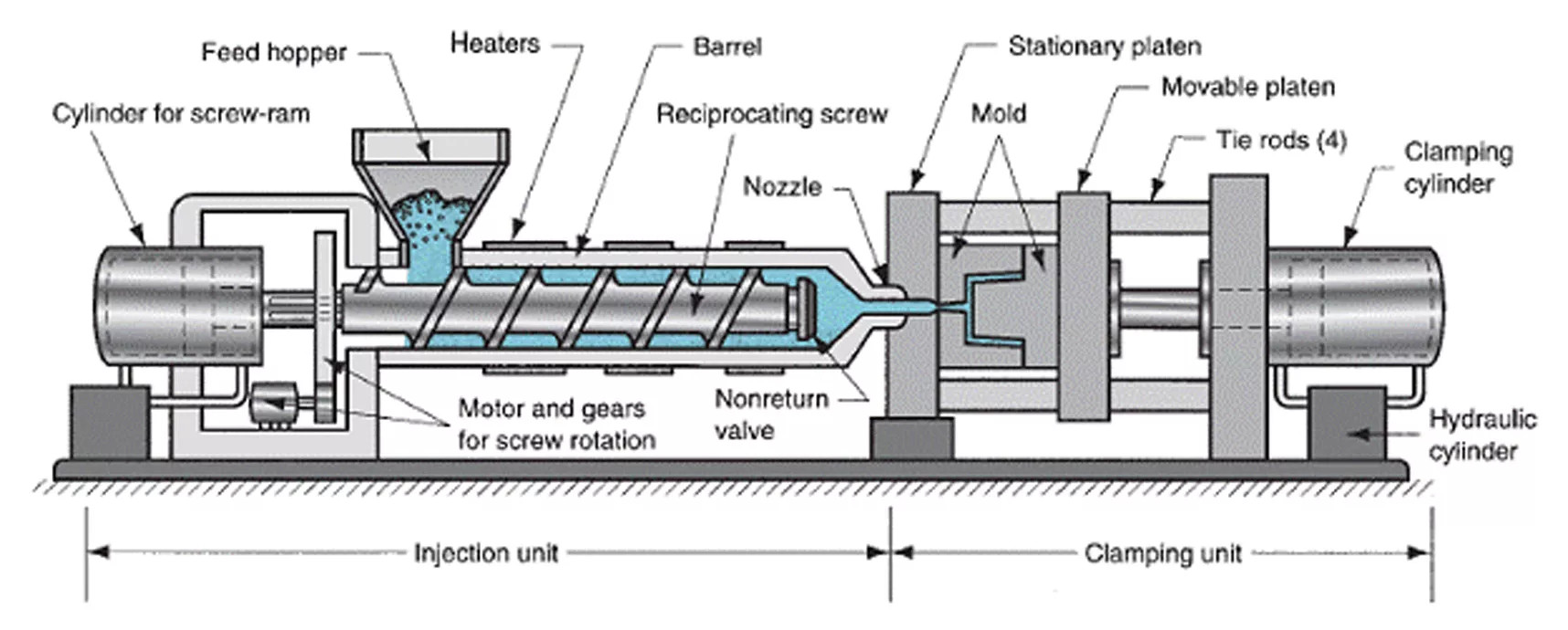

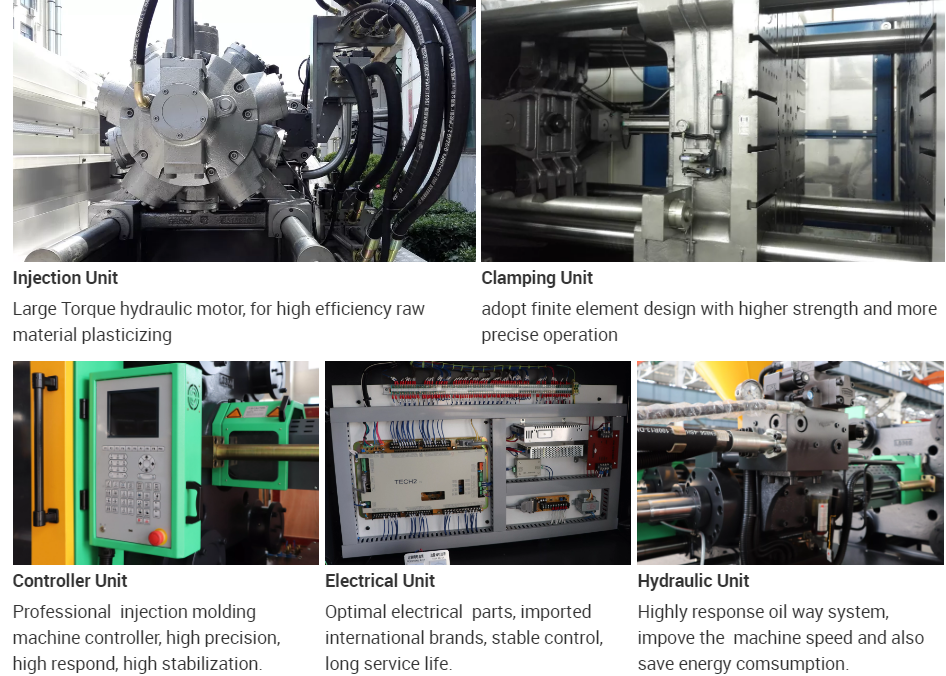

Plastic Injection Moulding Machine.Adopting Europe technology,hydraulic unit adopts proportional pressure and flow control,the pressure and the speed can be adjusted,stable movement curve and gentle shock,the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’s safety.

Product Highlights

1. High-Efficiency Production for 5-Gallon PET Caps

Equipped with a dual-station injection system, this machine delivers 24-32 bottle caps per cycle and a daily output of 80,000-120,000 pieces,

ideal for large-scale 5-gallon PET bottle cap manufacturing lines.

2. Precision Molding with Tight Tolerance

Adopts an imported servo-hydraulic system with a clamping force of 500-800KN, ensuring the dimensional tolerance of bottle caps is controlled

within ±0.02mm to match 5-gallon PET bottle mouth standards perfectly.

3. Intelligent PLC Control for Easy Operation

Features a 10.1-inch touch screen PLC control system, supporting one-click presetting of production parameters and real-time monitoring of process

curves, reducing human error and boosting production consistency.

4. Energy-Saving Design for Lower Operating Costs

Full electric drive configuration cuts power consumption by 30% compared to traditional models; the zoned temperature control heating system

further optimizes energy use for PP, PE, and PET raw material processing.

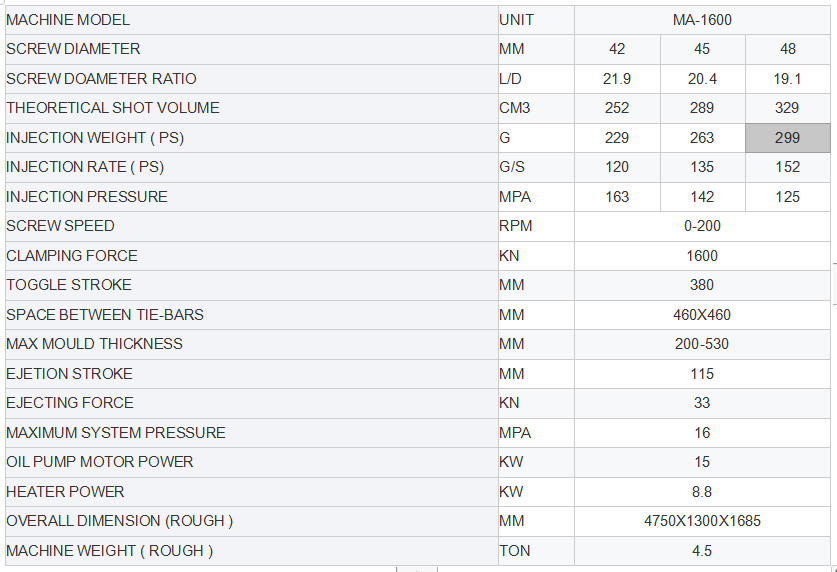

Technical Parameters

Parameter Item Specification Index

Injection Capacity 500-800g

Clamping Force 500-800KN

Mold Opening Stroke 300-450mm

Template Size 800×800mm

Machine Weight 5-8 tons

Power Supply Requirement 380V/50Hz 30KW

Application Scenarios

This 5-gallon PET bottle cap injection moulding machine is specially engineered for producing standard-caliber caps (φ55mm/φ60mm) for barreled

water, mineral water, and purified water 5-gallon containers. It supports seamless processing of multiple raw materials including PP, PE, and PET,

meeting the diverse needs of beverage packaging manufacturers.

Machine Technology:

Why Choose Us

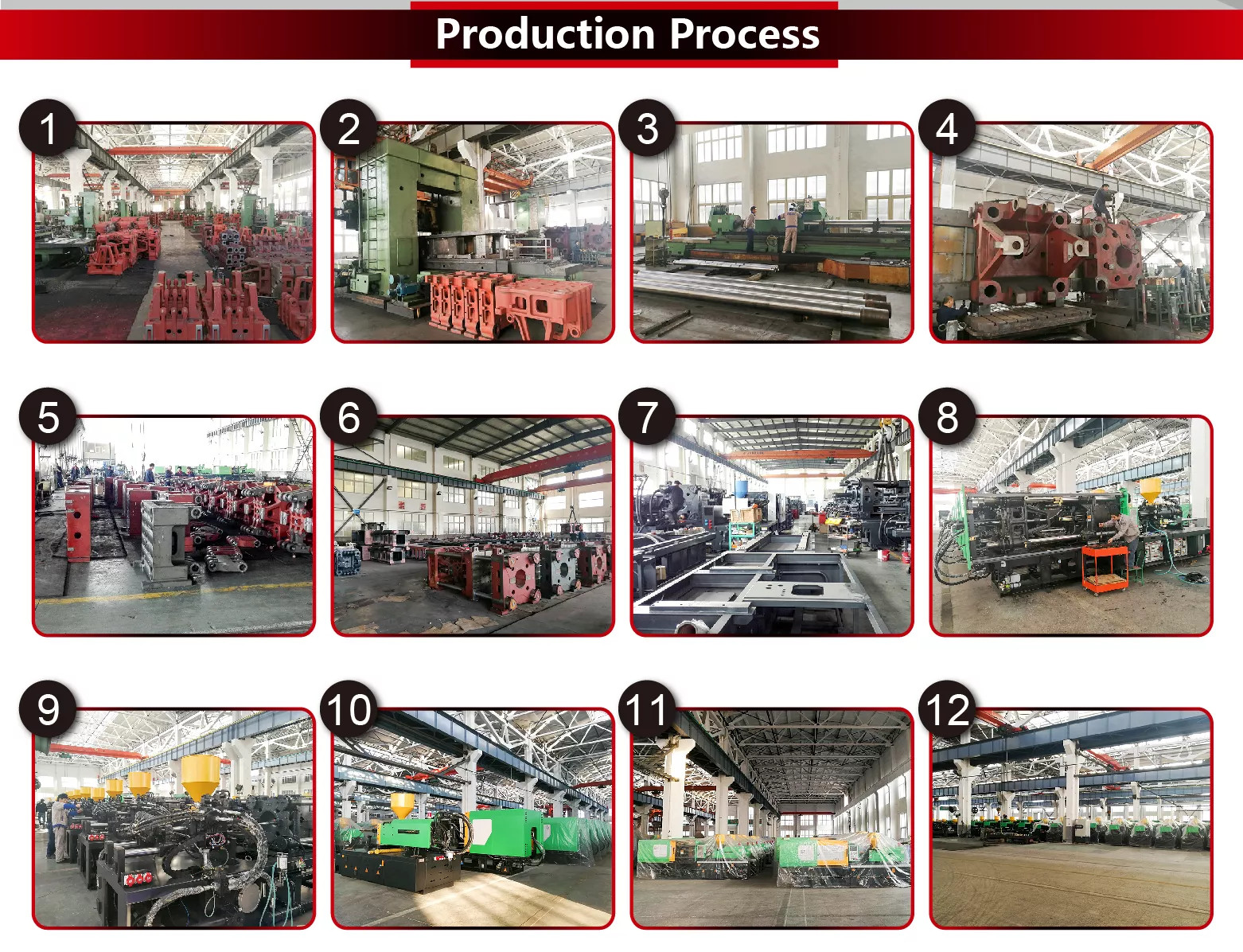

We have own machine design department, for new machine design, and each machine component are process in

our own workshop, to make sure strictly quality control. inspection team would check every machine before shipment,

keep every machine in good condition

Why Choose Us?

- Customizable mold solutions for non-standard 5-gallon cap designs

- 12-month warranty and on-site installation & training services

- Global after-sales support with 24-hour technical response

Frequently Asked Questions (FAQ)

1. Q: What raw materials can this 5-gallon PET bottle cap injection moulding machine process?

A: It is compatible with common plastics such as PP, PE, and PET, which are widely used for 5-gallon bottle cap production.

2. Q: How long does it take to install and commission the machine after delivery?

A: Our professional technical team can complete on-site installation and commissioning within 3–5 working days, depending on the local site conditions.

3. Q: Is the machine customizable for non-standard 5-gallon bottle cap sizes?

A: Yes, we provide customized mold matching services according to your specific cap dimensions and design requirements, to meet personalized production needs.

4. Q: What kind of after-sales support do you offer?

A: We provide a 12-month warranty for the machine, 24-hour online technical consultation, and on-site maintenance services if necessary.

5. Q: What is the power supply requirement for this machine?

A: The machine requires a 380V/50Hz 30KW power supply, and we can also provide voltage-adjusted versions for different regional standards upon request.

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat