Email: info@massfilling.com Tel: +86 133 5803 8863

As a child, one of the things I looked forward to at the start of the school term was buying new stationery. What many people don’t realize

is that those seemingly simple items—like a ballpoint pen—are actually feats of precision engineering.

How Hard Is It to Make a Ballpoint Pen?

A ballpoint pen works thanks to a tiny ball at the ball pen tip that rotates as it moves across the paper. This rotation draws ink from the cartridge

and transfers it smoothly onto the page.

In structural terms, the ball tip pen works by seating a tiny metal ball securely at the end of the pen’s ball base. This ball must rotate freely, without

falling out—a design that sounds simple but demands extremely high manufacturing precision.

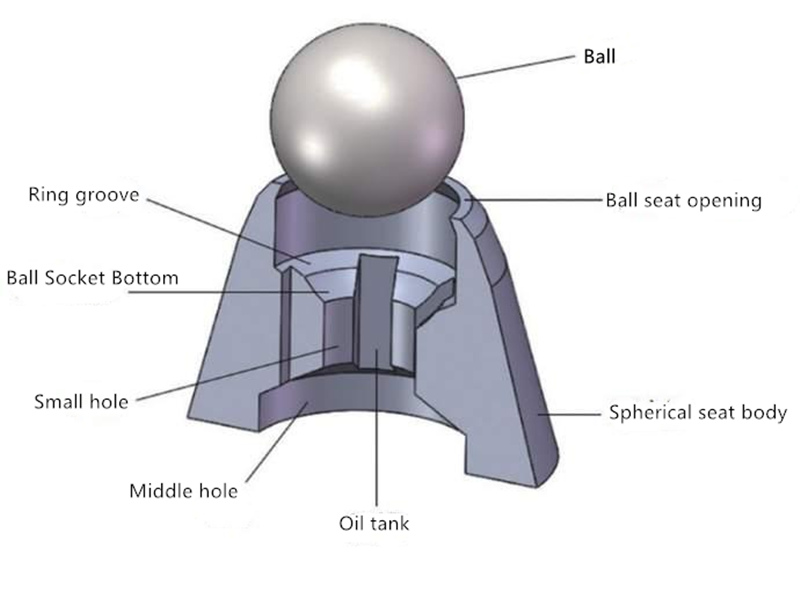

The internal structure of a ballpoint pen tip

There are three main technical challenges in producing a high-quality ballpoint pen tip:

1. Fit Between the Ball and the Socket

For smooth writing, the gap between the ball and the socket must be just right—around 5 microns. If it’s too small, ink won’t flow. Too large,

and the pen may leak or even lose the ball entirely.

2. Durability Under Friction

As the ball pen tip rolls across paper, friction gradually widens the gap between the ball and its housing. Over time, this can cause ink leakage

and degrade writing quality.

3. Ultra-High Machining and Assembly Accuracy

Inside the ballpoint pen tip, there are micro-grooves and channels that guide the ink. These must be machined to tolerances within 1 micron—a

testament to the incredible accuracy required in a ball tip pen.

All of these factors place high demands on the materials and production processes used to create the ballpoint pen tip. From the ball itself to the

internal structure of the tip, every component must meet strict standards to deliver the reliable performance we often take for granted.

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat