Email: info@massfilling.com Tel: +86 133 5803 8863

The high-pressure inner and outer drum washing machine is a revolutionary product of the drum washing machine. It is the killer of stubborn stains on green moss: the high-pressure inner and outer drum washing machine can solve the pain points of washing in water plants.

360 degree * * * high-pressure water jet cleaning. Forward and reverse solve the problem of difficult cleaning of the inner wall and bottom of irregular barrels.

20-120 kg pressure regulation. Clean with a brush outside.

There is no residue on the inner and outer walls, and there is no wear or scratch on the barrel.

Automatic high pressure 5 gallon drums inside and outside brushing machine 19 L 20 L bottle barrel internal external washer

Product Description

Machine description:

Automatic 18.9L barrel washing machine is a special cleaning equipment for cleaning the inside and outside of 18.9L barrel. Its design is novel and unique,

and the design of brush is also unique. This equipment use the integration of machine, electricity, gas. No need manual,high automatic, improve efficiency and

save cost. It can be customized according to the needs of manufacturers, while cleaning the inside and outside of the barrel, high efficiency. It is the best supporting

equipment for automatic filling machine.

The whole machine is relatively closed to prevent water from spilling out. When the bottle is sent to the washing bottle position by conveyor belt, the manipulator send

the barrel to the lifting position of the washing bottle, the lifting device will lift the bottle to the washing bottle position, the bottom brush will rise, clamping the bottle by

the manipulator, at the same time the brush and high pressure pump started, continuous injection of the barrel body, the bottle rotates with the brush, completely clean

bottle body, bottle neck, bottle bottom and bottle inside by brushand water. After the cleaning is completed, the lifting device and manipulator will send the bottle to the

conveyor belt, the bottle is sent to the next process by conveyor belt. The whole machine is controlled by PLC and equipped with independent control electrical box.

Main features:

The inside brushing adopts 360° rotating high-pressure nozzle for washing, without dead Angle, it can clean the visible in the barrel and solve the problem of losing

hair in the barrel. It is the best supporting equipment for automatic filling machine with high automatic, low labor cost, simple operation and convenient maintenance.

High pressure 5 gallon bottle brushing machine

Main technical parameter

Model | STNW-2 | STNW-3 | STNW-4 | STNW-5 | STNW-6 | STNW-8 | STNW-9 |

Capacity (18.9/BPH) | 150-200 | 200-300 | 400-450 | 550-600 | 750-800 | 900-1000 | 1000-1200 |

Suitable bottle shape and size | 10L 18.9L bottle (3&5 Gallon) | ||||||

Compressed air pressure | 0.3-0.7MPa | ||||||

Bottle washing medium | Sterile water | ||||||

Washing pressure | 0.25MPa | ||||||

Numbers of high pressure water pump | 2 | 3 | 4 | 5 | 6 | 8 | 9 |

Main motor (KW) | 1.5 | 9 | 12 | 18 | 20 | 24 | 27 |

Dimension(mm) | 1870*1550*2300 | 2050*1590*2500 | 2250*1620*2500 | 2430*1700*2300 | 2750*1720*2300 | 3100*1750*2500 | 3300*2000*2500 |

Weight(KG) | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 |

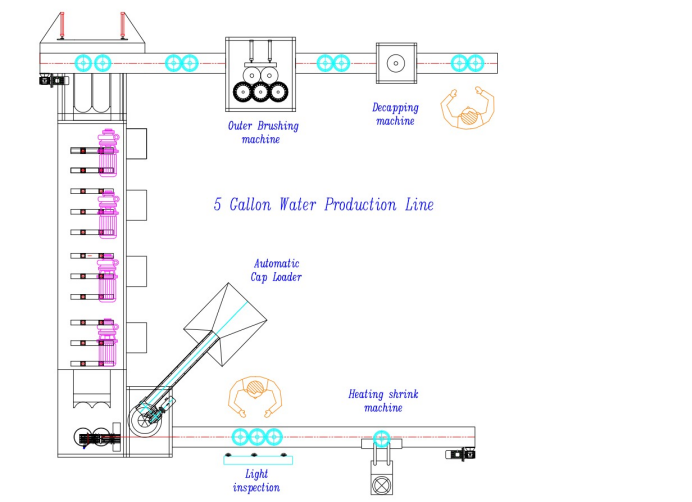

1.Decapping machine 2. bottle interior and exterior washing machine 3. 5 gallon washing filling capping machine 4. Sleeve shrink labeling machine

5. Bag packing machine 6. Palletizer

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat