Email: info@massfilling.com Tel: +86 133 5803 8863

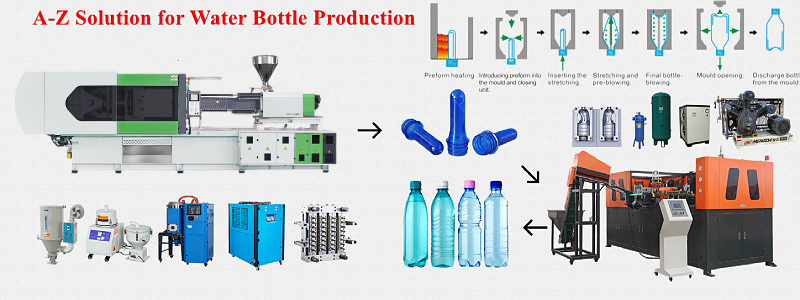

Plastic Injection Moulding Machine.Adopting Europe technology,hydraulic unit adopts proportional pressure and flow control,the pressure and the speed can be adjusted,stable movement curve and gentle shock,the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’s safety.

MA-4200PET preform injection machine(56cavity)

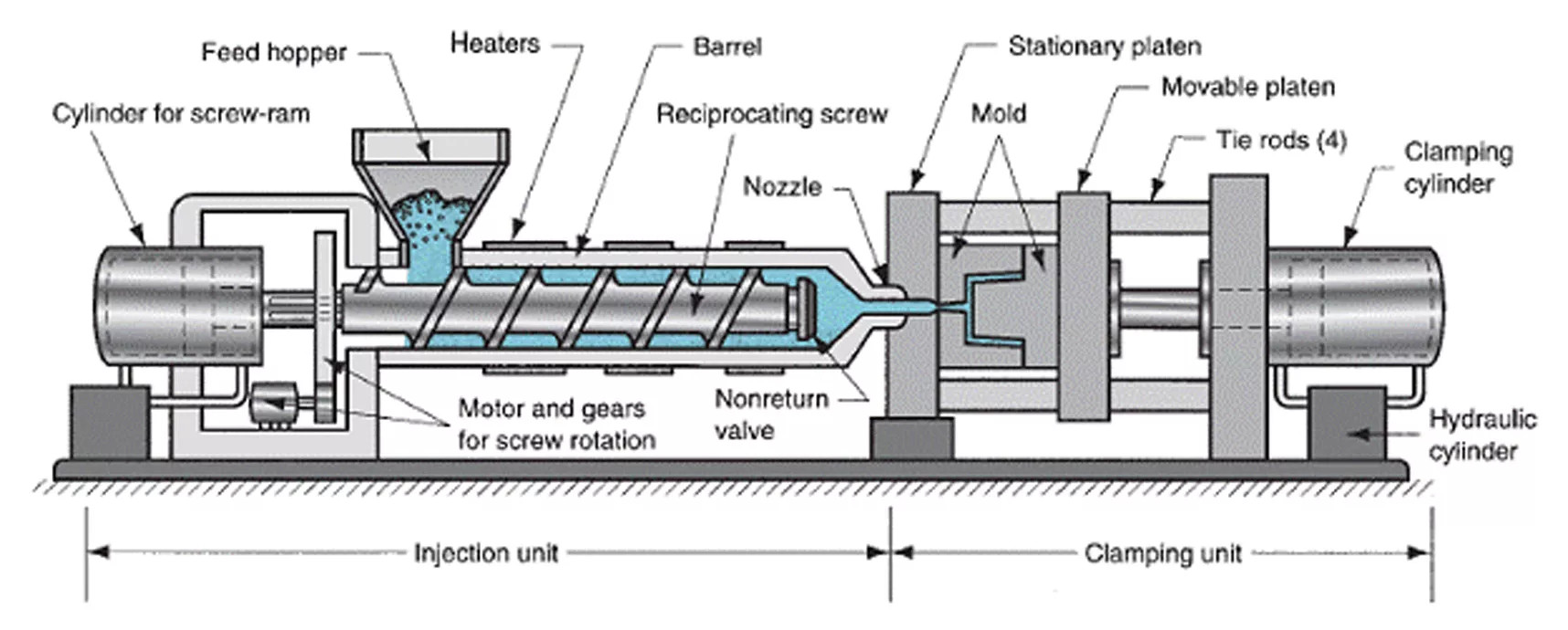

Machine Features:

1. Precision hydraulic synchronous template adjusting system

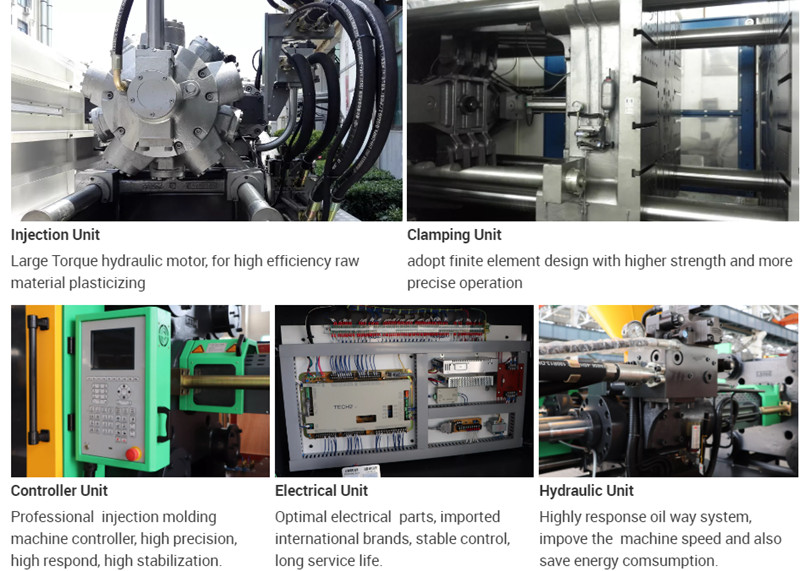

2. Optimal design of high-strength precision clamping structure, Clamping unit rigidity and accuracy

3. Large colorful screen high-precision computer system, precision control, easily operation, multi operation language available.

High-precision displacement sensor system, temperature control accuracy, big capacity data storage and date protection ability

4. World famous brand electrical system

5. Balanced type of double injection cylinder, eliminate oblique torque, diminishes deformation of screw and barrel, extend life

of screw ad barrel, optimizes plasticizing effect. Machine injection under multi-pressure and at various speed, with big capacity hydraulic motor.n

6. Large torque oil motor

7. Highly abrasion resistant alloy sliding block

8. The integrate type oil detachable oil tank, magnetic filter and bypass strainer. Reasonable and highly efficient lubrication system.

Modularized energy conservation high response oil system

9. Highly precise transducer, multi-stage control of opening stroke, speed and position. Flexible tie bars nut eliminate fatigue fracture,

assure tie bars long working life.

10. Security door fitted with hydraulic, mechanical and electrical interlocking triple safety device, fully protect machine operator.

11. Energy saving system, no extra energy consumption due to output volume changes according to load alteration. During stage

of holding pressure, servo motor lower down energy consumption, 0 energy consumption during machine cooling stage, save 20%-80%

energy consumption compare with standard machine.

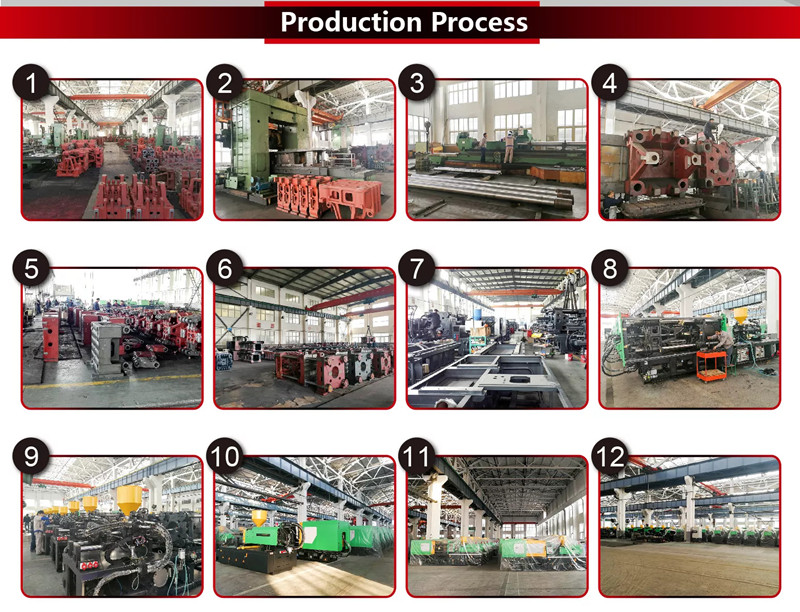

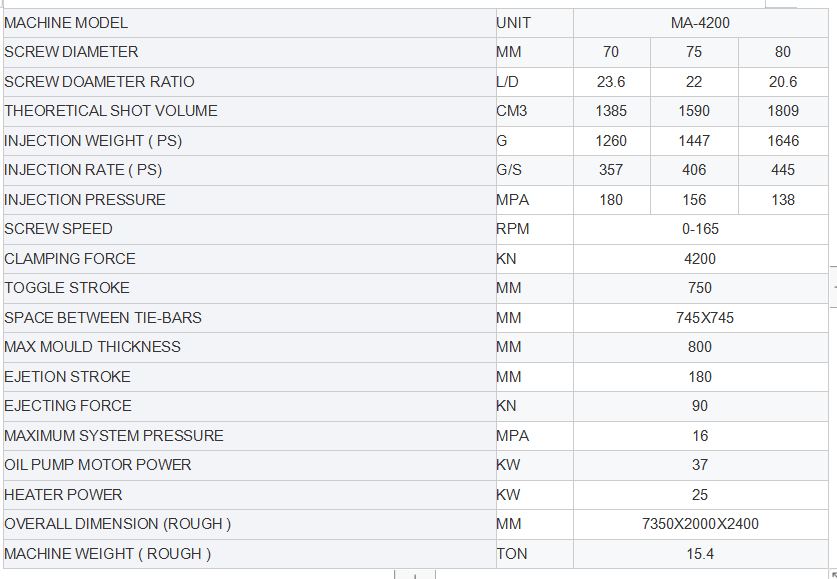

Machine Technology:

Packing &Delivery

1. the drinking pure water filling machine is packed by wooden case.

2. The delivery date of drinking pure water filling machine is within 30 days after payment.

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat