Email: info@massfilling.com Tel: +86 133 5803 8863

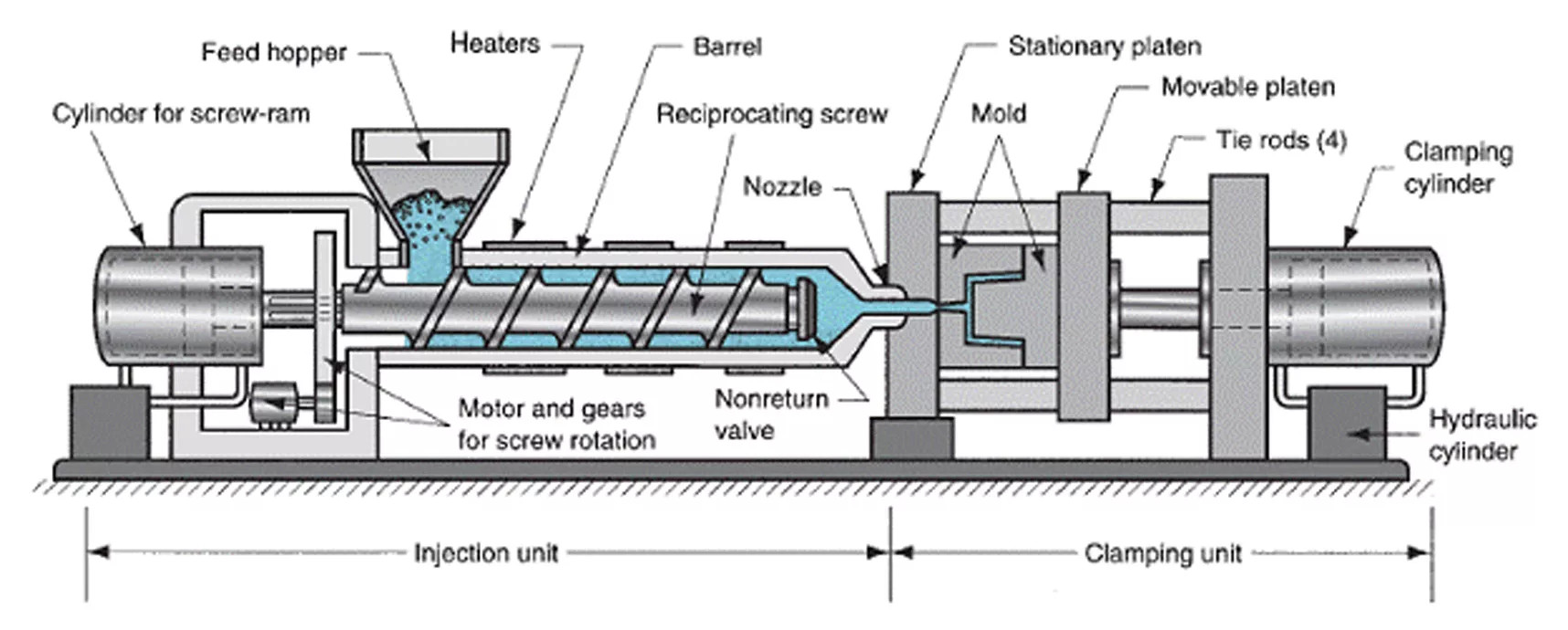

Plastic Injection Moulding Machine.Adopting Europe technology,hydraulic unit adopts proportional pressure and flow control,the pressure and the speed can be adjusted,stable movement curve and gentle shock,the computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to use. Close-loop PID temperature control with the advantage of high precision. The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators’s safety.

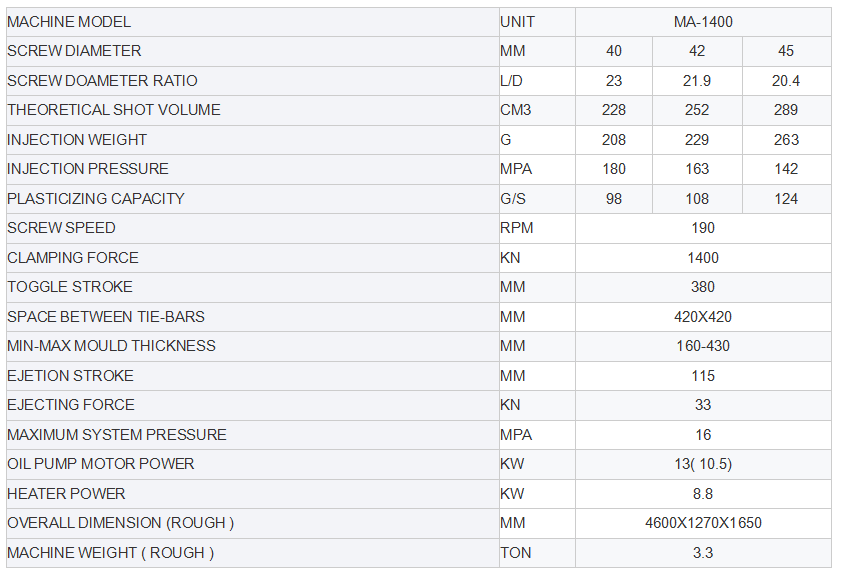

MA-1400PET preform injection machine(8cavity)

Machine Features:

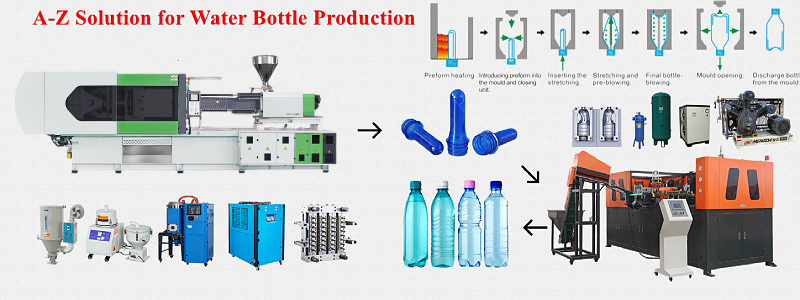

The MA-1400PET preform injection machine (8-cavity) is a flagship piece of equipment for PET preform manufacturing, specifically optimized for

water bottle preform production as part of our A-Z Solution for Water Bottle Production. This 8-cavity injection machine integrates advanced hydraulic,

electrical, and control systems to deliver exceptional precision, durability, and energy efficiency—making it a cornerstone of medium and large-scale

PET preform production lines.

Designed to meet the strict quality standards of the beverage packaging industry, the MA-1400PET preform injection machine produces consistent,

high-quality PET preforms for mineral water bottles, beverage bottles, and other plastic containers. Its 8-cavity mold design balances production speed

and molding accuracy, ensuring cost-effective and reliable preform manufacturing.

Core Features of MA-1400PET Preform Injection Machine (8-Cavity)

1. Precision Hydraulic Synchronous Template Adjustment System

Ensures seamless and uniform template alignment, laying the foundation for high-precision preform molding and reducing mold wear.

2. High-Strength Precision Clamping Structure

Optimized design delivers superior clamping unit rigidity and accuracy, maintaining stable mold closure during high-speed injection for consistent

preform dimensions.

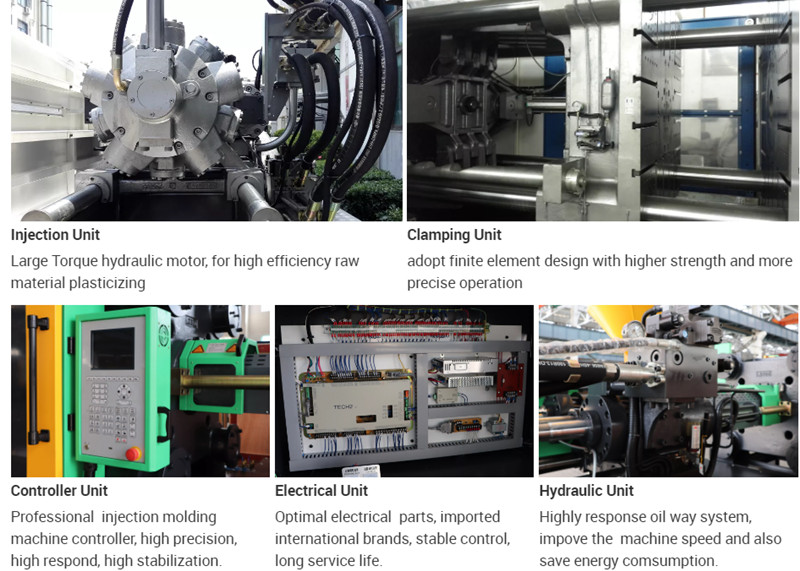

3. Advanced Color Screen Control System

Equipped with a large color touchscreen and high-precision computer control system, enabling intuitive operation, multi-language support, and precise

process control. Features a high-precision displacement sensor system for accurate temperature regulation, plus large-capacity data storage and protection

to preserve production parameters.

4. World-Class Brand Electrical System

Integrates components from internationally renowned electrical brands, guaranteeing stable performance, low failure rates, and easy maintenance for continuous production.

5. Balanced Double Injection Cylinder

Eliminates oblique torque during injection, minimizing deformation of the screw and barrel to extend their service life. Optimizes plasticizing effects and

enables multi-pressure, variable-speed injection with a large-capacity hydraulic motor.

6. High-Torque Oil Motor

Delivers powerful and stable power for the injection system, supporting the high-demand plasticizing and injection processes of 8-cavity preform production.

7. High Abrasion-Resistant Alloy Sliding Block

Reduces friction and wear in moving parts, enhancing the machine’s durability and ensuring smooth operation over long production cycles.

8. Integrated Detachable Oil Tank & Efficient Lubrication System

The integrated oil tank features a magnetic filter and bypass strainer to keep hydraulic oil clean, while the high-efficiency lubrication system ensures all

mechanical parts are properly maintained for reliable performance.

9. Modular Energy-Saving High-Response Oil System

Combines energy conservation with fast hydraulic response, adapting to production load changes to minimize energy waste without compromising performance.

10. High-Precision Transducer for Motion Control

Enables multi-stage control of mold opening stroke, speed, and position. Flexible tie bars prevent fatigue fracture, ensuring an extended service life for the machine’s

structural components.

11. Triple Interlocking Safety Protection

The safety door is fitted with hydraulic, mechanical, and electrical interlocking devices, providing comprehensive protection for machine operators and meeting industrial

safety standards.

12. Energy-Saving Servo System

Adjusts oil output according to load variations, eliminating excess energy consumption during the holding pressure stage. The servo motor cuts energy use by 20%–80%

compared to standard machines, and consumes no energy during the cooling phase—delivering significant cost savings for long-term production.

Machine Technology:

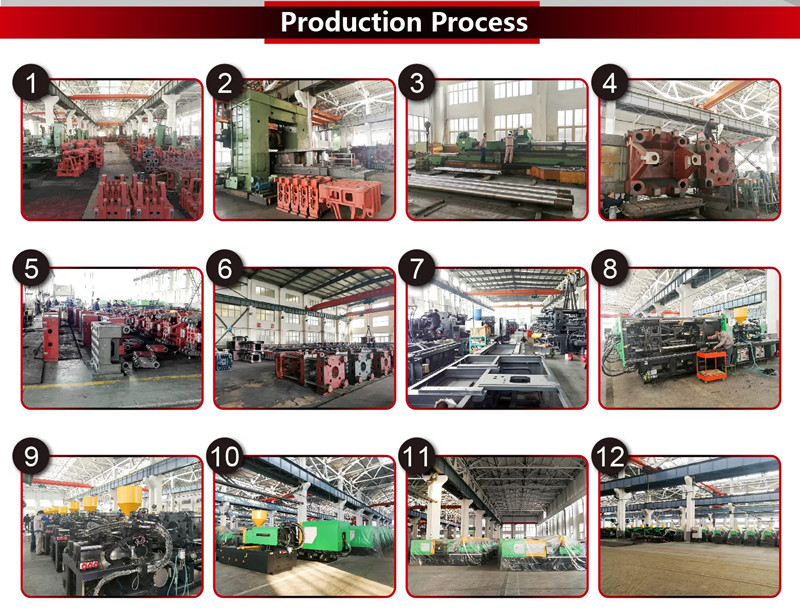

Packing &Delivery

1. the drinking pure water filling machine is packed by wooden case.

2. The delivery date of drinking pure water filling machine is within 30 days after payment.

FAQ About MA-1400PET Preform Injection Machine (8-Cavity)

Q1: What is the production output of this 8-cavity preform injection machine?

A1: For standard 500ml water bottle preforms, the machine can produce 1,500–3,000 preforms per hour (output varies by preform size and material).

Q2: Can the machine be adapted for non-water bottle preform production?

A2: Yes. By replacing the mold set, the MA-1400PET preform injection machine can produce preforms for cosmetic bottles, sauce bottles, and other plastic containers.

Q3: What after-sales services are included with the machine?

A3: We offer on-site installation, commissioning, and operator training, plus 24/7 technical support and a 12-month warranty for key components.

H2: Elevate Your Preform Production with MA-1400PET

Ready to upgrade your PET preform manufacturing with the high-performance MA-1400PET 8-cavity preform injection machine? Contact our team today for a customized

quote and detailed technical specifications, and let our A-Z water bottle production solution optimize your entire production line.

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat