Email: info@massfilling.com Tel: +86 133 5803 8863

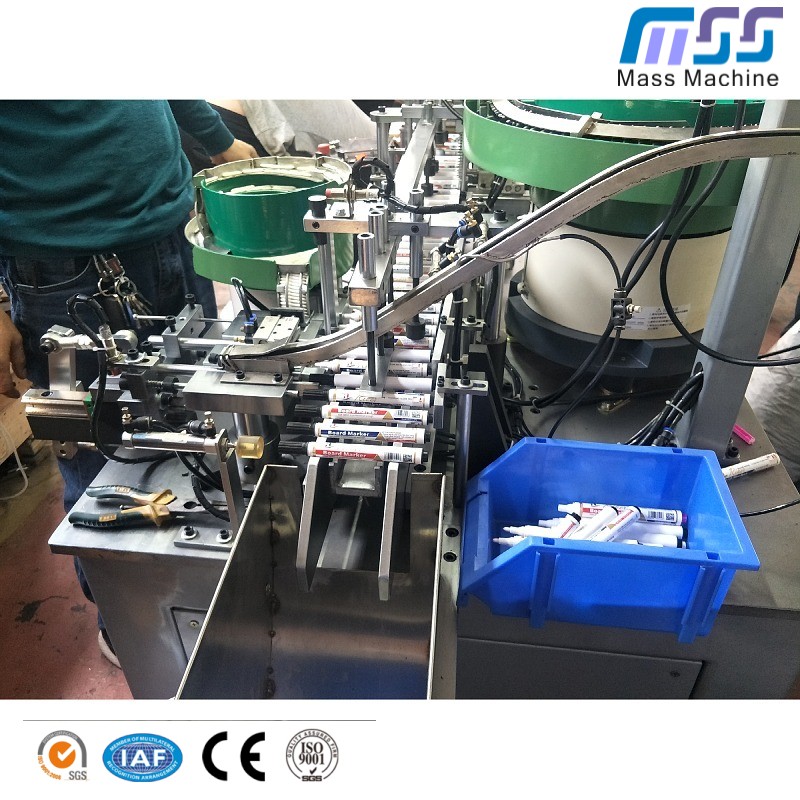

Intelligent control parts :operation easily by use of high quality PLC and touch panel,along with variable frequency regulating speed technology,else saves energy mechanical transpiration parts

Whiteboard Marker Pen Machine

In the competitive stationery manufacturing industry, the whiteboard marker pen machine is a game-changing equipment that streamlines

the final production stage—integrating pen barrels, ink reservoirs, tips, caps, and clips into finished, functional markers. Whiteboard marker assembly

requires meticulous alignment to ensure leak-proof performance, smooth ink flow, and durable structure—tasks that manual assembly struggles to

execute consistently at scale. Whether you’re a small factory reducing labor costs or a large enterprise boosting production capacity, the right whiteboard

marker pen machine delivers uniform quality, faster output, and lower operational expenses.

Our whiteboard marker pen machine is engineered exclusively for whiteboard marker production, combining automated multi-step assembly, precision

alignment technology, and user-friendly controls. Below, we detail key features, applications, technical highlights, and benefits to help you elevate your marker manufacturing line.

Unlike manual labor, our machine integrates all core assembly processes in one workflow: feeding pen barrels, inserting ink reservoirs, attaching precision

tips (fine/broad), sealing caps, and installing clips. The servo-driven automated system ensures each step is executed with consistent force and alignment,

eliminating human error (e.g., misaligned tips, loose caps) that causes ink leakage or poor writing performance. With a production speed of 30–60 markers

per minute, it outperforms 5–8 manual workers, significantly boosting output.

Whiteboard markers rely on airtight assembly to prevent ink leakage—our machine’s optical alignment technology ensures ink reservoirs fit perfectly into barrels,

and tips are seated tightly with zero gaps. The pressure-controlled cap sealing module applies uniform force, creating a secure seal that preserves ink freshness.

This precision reduces defective products to less than 0.3%, far below the industry average for manual assembly.

Our whiteboard marker pen assembly machine adapts to diverse marker styles and sizes: fine-tip (0.5–1.0mm), broad-tip (2.0–5.0mm), ergonomic grip barrels,

and branded markers with custom clips. Quick-change tooling (10–15 minutes) allows seamless switches between product models, supporting small-batch custom

orders and large-scale mass production alike. It’s compatible with PP, ABS, and ink-resistant plastic components, matching the output of most whiteboard marke

r injection molding machines.

The intuitive touchscreen control panel stores 50+ production recipes, enabling operators to adjust speed, pressure, and assembly steps with minimal training.

Real-time monitoring alerts users to jams, material shortages, or alignment issues, minimizing downtime. Built with corrosion-resistant components and a modular

structure, maintenance is simple—most parts are easily accessible and replaceable without specialized tools. We offer a 1-year warranty and lifetime technical support.

For enterprises producing 100,000+ whiteboard markers daily (supplying schools, offices, or global brands), our high-speed models (50–60 markers/minute) deliver 24,000+ finished

markers per 8-hour shift. Automated operation reduces labor costs by 60–70% compared to manual assembly lines, while consistent quality enhances brand reputation.

Mid-range models (30–40 markers/minute) excel at small-batch, branded markers (3,000–10,000 units) for corporate events, school souvenirs, or marketing giveaways. Quick tooling

changes and recipe storage ensure efficient production of custom designs without sacrificing speed.

Entry-level models (30 markers/minute) suit daily outputs of 5,000–30,000 markers. Compact design fits small workshops, and user-friendly controls require minimal staffing—ideal

for businesses looking to scale without large labor investments.

Pair our whiteboard marker pen assembly machine with injection molding equipment to create a full production line. The synchronized workflow (molding → assembly) reduces

material handling time, further boosting efficiency and lowering production costs.

• High Efficiency: Automates assembly to replace manual labor, doubling production capacity.

• Superior Quality: Precision alignment ensures leak-proof, durable markers with 3% defect rate.

• Cost Savings: Reduces labor, material waste, and rework expenses.

• Versatility: Adapts to fine-tip, broad-tip, custom, and branded marker designs.

• Specialized Design: Tailored exclusively for whiteboard marker assembly, outperforming general-purpose pen assembly machines.

• Automated Precision: Eliminates human error to deliver consistent, high-quality markers.

• Comprehensive Support: Pre-sales line design consultation, on-site installation, operator training, and after-sales maintenance.

Our whiteboard marker pen machine transforms marker production with automated precision, efficiency, and versatility. Whether you’re scaling up mass production

or meeting custom order demands, it ensures reliable output of leak-proof, durable whiteboard markers while cutting operational costs. Contact us today for quotes, line integration

advice, or factory visits to optimize your marker manufacturing process.

For enterprises producing 100,000+ whiteboard markers daily (supplying schools, offices, or global brands), our high-speed models (50–60 markers/minute) deliver 24,000+ finished

markers per 8-hour shift. Automated operation reduces labor costs by 60–70% compared to manual assembly lines, while consistent quality enhances brand reputation.

Mid-range models (30–40 markers/minute) excel at small-batch, branded markers (3,000–10,000 units) for corporate events, school souvenirs, or marketing giveaways. Quick tooling

changes and recipe storage ensure efficient production of custom designs without sacrificing speed.

Entry-level models (30 markers/minute) suit daily outputs of 5,000–30,000 markers. Compact design fits small workshops, and user-friendly controls require minimal staffing—ideal for

businesses looking to scale without large labor investments.

Pair our whiteboard marker pen assembly machine with injection molding equipment to create a full production line. The synchronized workflow (molding → assembly) reduces

material handling time, further boosting efficiency and lowering production costs.

• High Efficiency: Automates assembly to replace manual labor, doubling production capacity.

• Superior Quality: Precision alignment ensures leak-proof, durable markers with 3% defect rate.

• Cost Savings: Reduces labor, material waste, and rework expenses.

• Versatility: Adapts to fine-tip, broad-tip, custom, and branded marker designs.

• Specialized Design: Tailored exclusively for whiteboard marker assembly, outperforming general-purpose pen assembly machines.

• Automated Precision: Eliminates human error to deliver consistent, high-quality markers.

• Comprehensive Support: Pre-sales line design consultation, on-site installation, operator training, and after-sales maintenance.

Our whiteboard marker pen machine transforms marker production with automated precision, efficiency, and versatility. Whether you’re scaling up mass production

or meeting custom order demands, it ensures reliable output of leak-proof, durable whiteboard markers while cutting operational costs. Contact us today for quotes, line integration

advice, or factory visits to optimize your marker manufacturing process.

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat