Email: info@massfilling.com Tel: +86 133 5803 8863

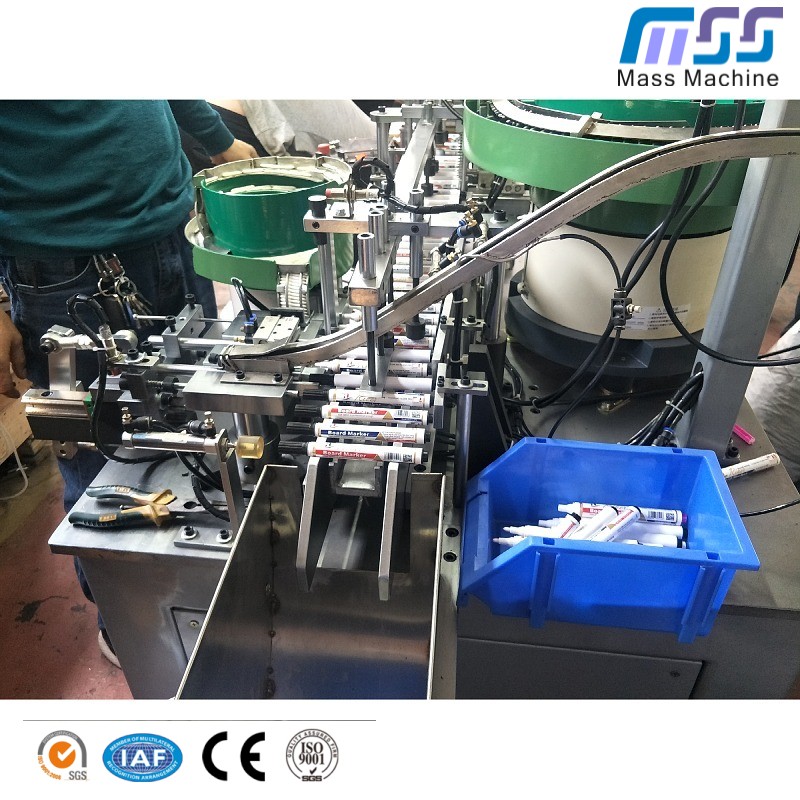

Intelligent control parts :operation easily by use of high quality PLC and touch panel,along with variable frequency regulating speed technology,else saves energy mechanical transpiration parts

Whiteboard Pen Assembly Machine: Professional Automation Solution for Pen Production

The whiteboard pen assembly machine has emerged as a transformative asset in modern writing instrument manufacturing,

addressing the unique assembly challenges of whiteboard pens with advanced automation. Unlike generic assembly machines

that struggle with the specialized components of whiteboard pens—such as porous nibs, ink reservoirs, and airtight caps—

this dedicated equipment streamlines the entire production workflow, from component feeding to final product inspection.

Crafted with industrial-grade steel frames and precision-machined parts, the whiteboard pen assembly machine ensures

consistent operation even during extended production runs. Its PLC control system enables precise parameter adjustment,

accommodating different whiteboard pen sizes (from standard to jumbo) and nib types (fiber or felt). This versatility makes

it suitable for both small-batch customization and large-scale mass production, meeting the diverse needs of pen manufacturers

targeting educational institutions, corporate offices, and stationery retailers.

In terms of performance, the assembly machine achieves a production speed of up to 200 whiteboard pens per minute, a

significant leap from manual assembly (typically 10-15 pens per minute). It minimizes human error by 95%, ensuring uniform

ink flow, secure nib attachment, and leak-proof cap fitting—critical quality factors for whiteboard pens used in high-frequency

writing scenarios. The machine’s integrated safety features, including emergency stop buttons and protective enclosures,

comply with international safety standards (CE, ISO), safeguarding operators and reducing workplace hazards.

Maintenance and usability are key design priorities. The machine features a modular structure that simplifies component

replacement and cleaning, reducing downtime. An intuitive touchscreen interface displays real-time production data

(output count, error rates, operating hours) and allows one-click parameter saving for recurring production tasks. For overseas

clients, we provide voltage adaptation (110-240V), multilingual operation guides, and remote technical support via video calls,

ensuring seamless integration into global production lines.

As the demand for high-quality whiteboard pens grows in education and corporate sectors, investing in a reliable whiteboard

pen assembly machine becomes a strategic choice. It not only cuts labor costs by 60% but also shortens production lead times,

enabling manufacturers to respond quickly to market orders. Whether upgrading existing facilities or building new production

lines, this assembly machine delivers long-term value by enhancing productivity, quality consistency, and market competitiveness.

Supplemented by our comprehensive after-sales service—including on-site installation, operator training, and spare parts supply—

the whiteboard pen assembly machine stands as a trusted partner for pen manufacturers aiming to scale operations and meet

global quality standards. Its combination of precision, efficiency, and adaptability makes it an indispensable tool in the evolving

landscape of writing instrument production.

Automatic whiteboard pen assembly machine

Intelligent control parts :operation easily by use of high quality PLC and touch panel,along with variable frequency

regulating speed technology,else saves energy

mechanical transpiration parts:take the use of high efficiency cams combined the precision machinery cam,are driver

by the same main power,which can make improvement the stabilization and life span.

automatically feeding system: feeding by way of vibration,the machine hands installation accurately,ensure the feeding

stabilization and security high quality

working speed:50-60pcs/min

Work station:double type

power:1.5kw

air : 5-6kgf/cm²

Working type :Automatically

Worker:1 people

Contact: Linda Ma

Phone: +86 136 1624 7328

E-mail: info@massfilling.com

Whatsapp: 8613616247328

Add: Leyu Development Zones,Zhangjiagang City,Jiangsu

We chat